| National Security Cutter (NSC) | 您所在的位置:网站首页 › DownloadwallpaperCoastGuardCutterStratton3840x2160 › National Security Cutter (NSC) |

National Security Cutter (NSC)

The Legend-Class National Security Cutters (NSCs) are being built by Huntington Ingalls Industries for the US Coast Guard (USCG). Image courtesy of Huntington Ingalls Industries.

National Security Cutter Stratton (WMSL 752) prepares to leave the dock at Ingalls Shipbuilding for Acceptance Trials. Image courtesy of Huntington Ingalls Industries.

The port side view of the National Security Cutter USCGC Bertholf (WMSL-750), Image courtesy of Tognum AG.

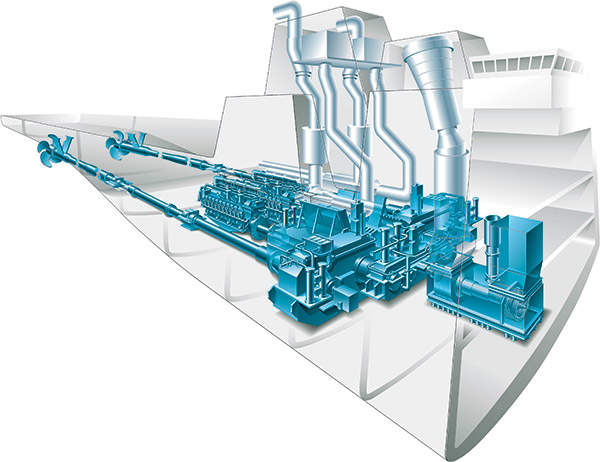

National Security Cutter (NSC) is powered by a CODAG (Combined Diesel and Gas turbine) propulsion plant supplied by MTU. Image courtesy of Tognum AG.

The Legend-Class National Security Cutters (NSCs) are a new class of vessels in service with the US Coast Guard. The NSCs are primarily intended for maritime homeland security and coastal defence missions. “In 2010, the US Coast Guard placed a production contract with Huntington Ingalls Industries (HII) for the fourth NSC.”The NSC project under the Deepwater Programme involves the acquisition of eight vessels to replace the ageing fleet of Hamilton-Class High Endurance Cutters. The first three cutters were acquired as part of a $17bn contract signed with Integrated Coast Guard Systems (a joint venture between Northrop Grumman and Lockheed Martin) for the Deepwater Programme. The Deepwater Programme involves acquisition of cutters, patrol boats, vessels and aircraft to replace the ageing fleet of the US Coast Guard (USCG). In November 2010, the US Coast Guard placed a production contract with Huntington Ingalls Industries (HII) for the fourth NSC. HII received a $482m fixed-price incentive contract for the fifth cutter in September 2011. The US Coast Guard placed a $76m fixed-price contract with HII in March 2012 for the acquisition of long-lead materials for the sixth cutter. The US Coast Guard inducted three vessels into service by March 2012. These Coast Guard Cutters are homeported at USCG Base Alameda. Construction and commissioning of the USCG CuttersThe keel for the first ship in the class, USCGC Bertholf (WMSL-750), was laid down at HHI shipyard in Pascagoula in March 2005. The cutter was launched in September 2006 and commissioned into service in August 2008. Waesche (WMSL-751) was laid down in September 2006, launched in July 2008 and commissioned in May 2010. The third ship in class, USCGC Stratton (WMSL-752), was laid down in July 2009. It was commissioned into service in March 2012. USCGC Hamilton’s (WMSL-753) keel was laid down in September 2012 for the delivery in the third quarter of 2014. The prefabrication activities for the fifth NSC in class, Joshua James (WMSL-754), began in March 2012. National Security Cutter (NSC) design and featuresThe NSC is the largest and most technically sophisticated vessel in the Coast Guard fleet. “The first three cutters were acquired as part of a $17bn contract signed with Integrated Coast Guard Systems.”The USCG technical experts raised questions on its structural design after a review. The structural deficiencies were subsequently resolved to achieve a 30-year service life. The NSC has a length of 127.4m, a beam of 16.4m and a draft of 6.8m. The displacement of the vessel is 4,400t. The ship can carry 122 crew members, along with food and supplies sufficient for 60 days. The cutters are also capable of conducting refuelling at sea for extended patrols. Each cutter can carry and launch two Over-the-Horizon IV Cutter Boats and a Long Range Interceptor II (LRI-II) boat for extended operations. Command and controlThe Coast Guard Command and Control (CGC2) aboard the NSC allows interoperability between other vessels in the fleet. The C4ISR system integrates an identification friend or foe transponder, an automatic identification system, electro-optical / infrared sensor system, AN/SPS-73 surface search radar and TRS-3D/16-ES air search radar. The cutters are also equipped with Sensitive Compartmented Information Facility (SCIF) and L-3 Deepwater Radio Frequency Communication Systems. Weapon systems onboardThe National Security Cutters are armed with a Mk 110 57mm naval gun system, a Phalanx 20mm Close-In Weapon System (CIWS), four .50 calibre machine guns and two M240B 7.62mm machine guns. The Mk 110 can fire 220 rounds a minute for a maximum range of 17km. The onboard Phalanx CIWS protects the cutter from close-in air and high-speed surface threats. NSC flight deck detailsThe large flight deck of NSC can accommodate two MH-65D Dolphin helicopters or a single MH-65D and two Unmanned Aircraft Systems (UAS). Two level one, class one aircraft hangars are provided for the storage of embarked helicopters. The flight deck also supports vertical replenishment (VERTREP) operations. Countermeasure technologyThe countermeasures are provided by an AN/SQL-32 electronic warfare (EW) system, two Mk 53 Nulka decoy launching systems and two Mk 36 super rapid blooming off-board chaff launch systems. The Nulka system deceives incoming radar homing anti-ship missiles by launching decoys. Propulsion systems on the US Coast Guard vessels

CODAG (combined diesel and gas) propulsion system The NSCs are equipped with an MTU CODAG (combined diesel and gas) propulsion system. The CODAG propulsion plant integrates two 7,400kW 20V 1163 diesel engines and one 22,000kW GE LM2500 gas turbine. The twin diesel engines and gas turbine drive system runs two controllable / reversible pitch propellers via a cross-connected reduction gear system. The onboard electricity is generated by three Caterpillar 3512B service diesel gensets. The propulsion system provides a maximum speed of 28kt and a range of 12,000nm. |

【本文地址】